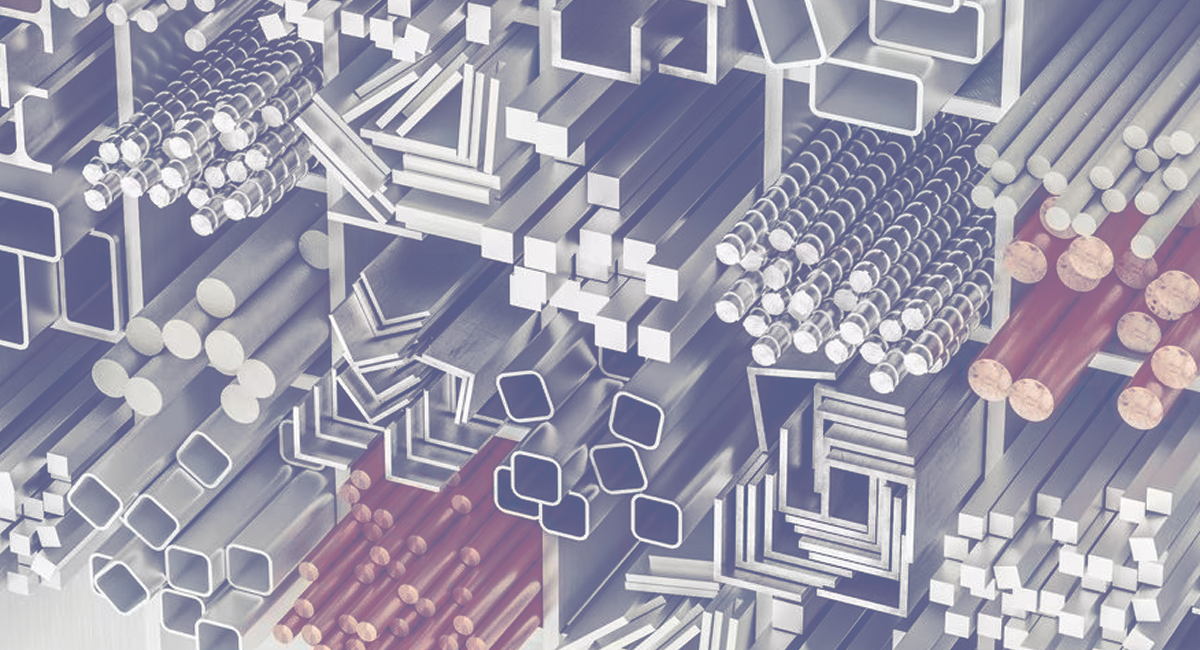

Importance of Material Selection in Fasteners (Steel, Stainless, Brass)

Fasteners are the backbone of countless applications across industries, from construction and automotive to furniture and electronics. While size, type, and design matter, the choice of material is equally critical.

The material directly affects the fastener’s strength, durability, resistance to corrosion, and suitability for specific environments. Among the most commonly used are steel, stainless steel, and brass, each offering unique benefits.

Commitment to Premium QualityAt Pooja Metal Industries, we prioritize excellence by using only premium-grade materials sourced from well-established and trusted suppliers. Our dedication ensures every fastener delivers unmatched strength, durability, and reliability, meeting global standards and exceeding customer expectations in every application.

Steel Fasteners – Strength and Economy

Steel fasteners are the most widely used due to their high tensile strength and affordability. They are ideal for heavy-duty applications where load-bearing capacity is crucial. Carbon steel variants offer extra hardness, making them suitable for structural and mechanical assemblies. However, without protective coatings (such as zinc or galvanization), steel fasteners may be prone to rust, limiting their use in outdoor or moisture-prone environments.

Stainless Steel Fasteners – Corrosion Resistance

Stainless steel fasteners stand out for their resistance to rust and corrosion, making them a preferred choice in marine, outdoor, and chemical exposure environments. Grades such as 304 and 316 provide a combination of strength and longevity. Though slightly costlier than regular steel, stainless steel ensures reliability and reduced maintenance, especially in harsh weather or corrosive conditions.

Brass Fasteners – Aesthetic and Non-Magnetic

Brass fasteners are valued for their attractive finish, non-magnetic properties, and natural corrosion resistance. Commonly used in electrical, plumbing, and decorative applications, brass combines moderate strength with excellent conductivity. Their golden appearance makes them ideal for visible installations where aesthetics matter, such as furniture or architectural fittings.

In conclusion, material selection in fasteners is not just a technical detail but a vital decision that influences performance, safety, and longevity. Steel offers strength at low cost, stainless steel ensures durability against corrosion, and brass provides both beauty and function. Choosing the right material ensures the fastener performs optimally for its intended application, ultimately delivering long-term reliability and value.