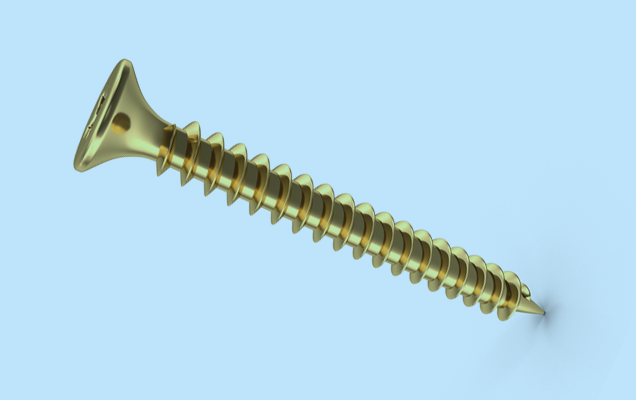

High-Precision Threading for Optimal Fastening.

Delivering consistent, high-quality threads customized to your specific needs.

Thread customization is an integral part of our fastening solutions, offering a wide range of threading options such as full thread, half thread, and saw cut thread to meet precise functional requirements across industries. Our advanced machining and tooling techniques ensure exceptional accuracy in thread formation across various diameters, lengths, and materials including stainless steel, mild steel, brass, or as per specific needs.

Through precision tooling and controlled production parameters, each thread is engineered to match the intended design and performance criteria. This results in uniform quality, a refined surface finish, and dependable functionality, whether for standard thread profiles or specialized custom forms.

With a strong emphasis on dimensional accuracy and consistency, we deliver uniform quality, refined surface finish, and reliable performance in demanding applications and assembly needs.

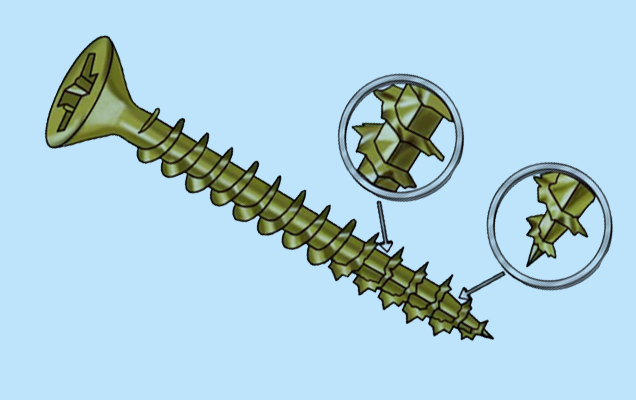

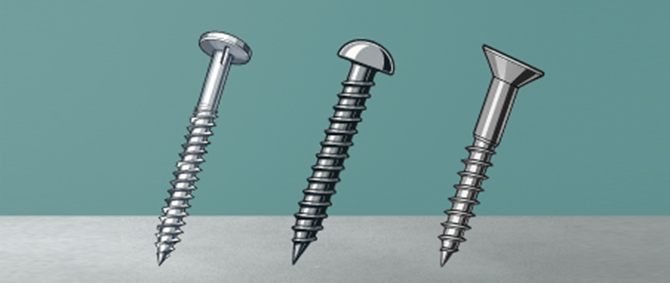

Full Thread

Achieve optimal material contact with full threads. Their continuous design enhances precision axial fit and evenly distributes load to outperform conventional half threads.

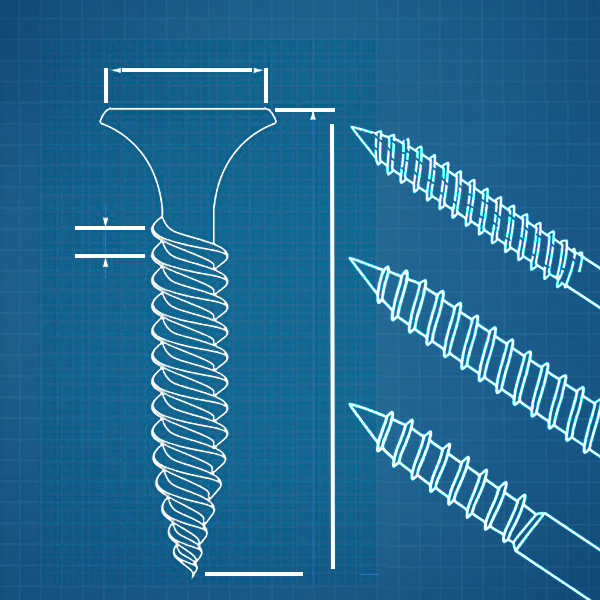

Half Thread

Built with partial threads for secure grip and a smooth shank for alignment, half-thread screws ensure superior strength, stability, and assembly precision over fully threaded types.

Saw Cut Thread

Featuring a non-symmetrical flank angle, saw cut threads concentrate force on one side, delivering exceptional stability and power for dynamic lifting and clamping applications.